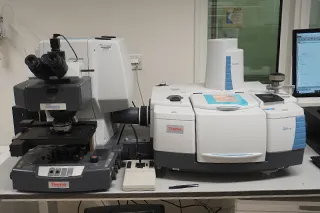

FT-IR stands for Fourier Transform InfraRed, the preferred method of infrared spectroscopy. In infrared spectroscopy, IR radiation is passed through a sample. Some of the infrared radiation is absorbed by the sample and some of it is passed through (transmitted). The resulting spectrum represents the molecular absorption and transmission, creating a molecular fingerprint of the sample. Like a fingerprint, no two unique molecular structures produce the same infrared spectrum. This makes infrared spectroscopy useful for several types of analysis. Irradiating a sample - whether solid, liquid or gas - with infrared light causes vibrational motion of covalently bonded groups of atoms (known as functional groups) that will each vibrate at a specific frequency. Thus, a fingerprint IR spectrum is produced that can be used to obtain valuable structural information about the material. Since different molecules have different structures, hence different IR fingerprints, FT-IR represents a robust tool to characterize the different functional groups in organic materials, and to a lesser extent in inorganic materials. Therefore, infrared spectroscopy can result in a positive identification (qualitative analysis) of every different kind of material.

Background of Thin Films Deposition using Physical Vapor Deposition techniques

Physical vapor deposition (PVD) considers various vacuum deposition techniques to grow pristine thin films and coatings for miscellaneous applications. In general, the entire working principle of PVD tools captures the vapor phase of source materials and condensed phase of deposited thin films. The most common PVD processes are sputtering and evaporation. PVD tools are well known in industry to develop devices for mechanical, optical, chemical, or electronic functions. Currently, our Thin Films Lab has three different PVD tools namely, Phoenix™ sputtering system, Explorer™ evaporator, and Veeco™ dual chamber molecular beam epitaxy (MBE) system.

For all the three techniques, uniform films of high purity can be achieved through cleaning the excess atmospheric particles under high vacuum deposition pressure. In a sputtering tool, atoms are ejected into the vapor phase in the presence of an inert process gas plasma, which is commonly Argon due to its inactive reaction nature with other molecules and tend to deposit on all surfaces in the vacuum chamber. Finally, a substrate placed in the chamber will be coated with a thin film.

In an evaporation tool, the basic working principle follows two phenomena. Firstly, the evaporation of hot source materials and secondly the condensation as thin films on the substrate. Like other PVD tools, evaporation happens under vacuum, hence, any other residuals are generally removed during the process using roughing as well as cryo pumps. Molecular Beam Epitaxy (MBE) is a significant deposition technique to grow epitaxial, layered structures under ultrahigh vacuum conditions on different substrate materials. In general, chemical reaction occurs through molecular beam impinging on the surface; this chemical reaction is the material transition from the gas phase in the molecular beam to the solid state on top of the substrate.