Overview

This initiative engineers advanced materials that adapt to extreme conditions, delivering sustainable, high-performance solutions across energy, water, environment, and critical infrastructure.

Projects

This project focuses on advancing material performance, corrosion mitigation, and degradation prevention across critical industrial, water, and energy infrastructure in Qatar-relevant harsh environments. It addresses key challenges of material degradation, such as coating failure under insulation and environmental exposure, chloride stress corrosion cracking of corrosion-resistant alloys, hydrogen embrittlement in both conventional and additive manufacturing materials for renewable energy systems, and microbiologically influenced corrosion (MIC) in Seawater Reverse Osmosis (SWRO) plants. The project combines experimental studies, rapid inhibitor screening, and field exposure testing to develop robust frameworks for protecting infrastructure integrity and water quality. It also investigates advanced methods for predicting and preventing corrosion through AI-driven models and multi-scale data integration. Key activities include optimizing corrosion inhibitors for Qatar’s brines, understanding hydrogen absorption in materials, improving coatings for extreme environmental conditions, and developing sustainable energy solutions, such as CO₂ capture materials and catalysts for sustainable aviation fuel. The work will lead to the creation of predictive models, validated corrosion testing standards, and guidelines for material selection, contributing to international standards and providing real-world, field-ready solutions for corrosion control in water and energy infrastructure. The project ensures the improvement of resilience of infrastructure via the employment of reliable materials and methodologies to enhance system longevity and performance in extreme environments.

The project aims to advance energy solutions by developing and integrating innovative materials and device architectures. It covers:

- Enhancing photovoltaic (PV) conversion efficiency through the incorporation of cutting-edge technologies, such as metamaterials, rectennas, and perovskite-based systems.

- Improving module durability by introducing advanced anti-dust and anti-reflective (AR) surface treatments to combat soiling and abrasion in harsh environments.

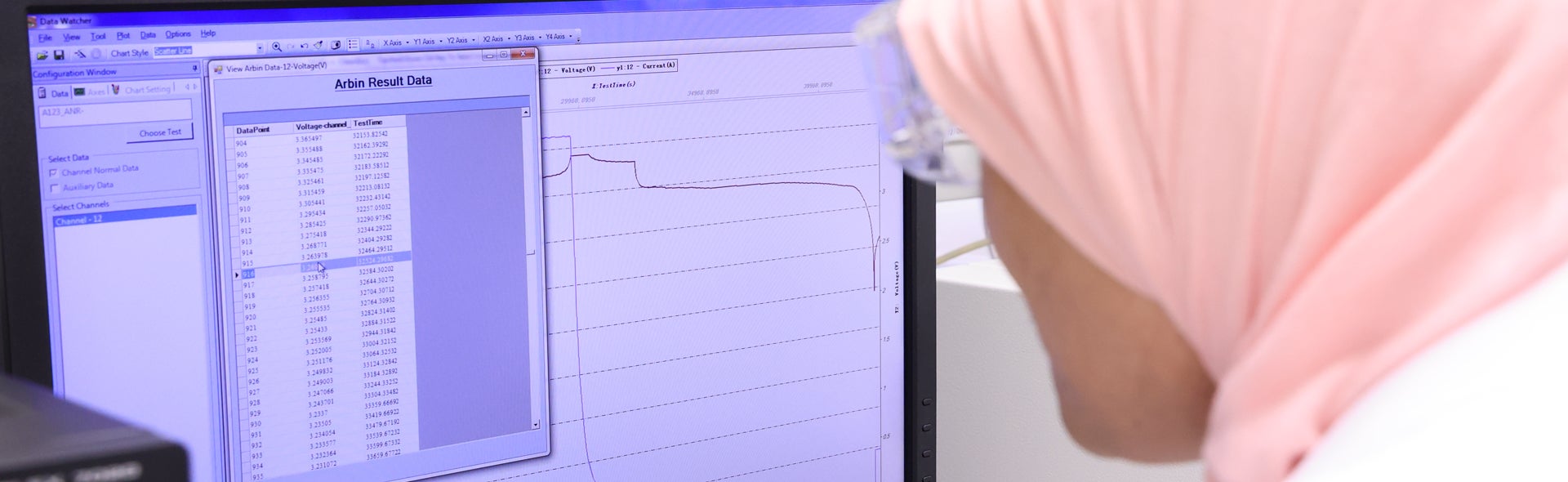

- Investigating, modeling, and mitigating the degradation mechanisms of batteries operating under extreme desert conditions.

This project serves as a critical bridge between laboratory-scale material innovations and real-world performance by leveraging field-deployable mini-modules and fostering bilateral collaborations to validate outcomes under operational conditions.

This project integrates non-destructive material analysis, accelerated aging and mechanism studies, and an AI-curated database to preserve Islamic manuscripts, focusing on iron gall ink and verdigris while expanding to broader pigment/ink families in early Qur’anic and related manuscripts (8th–12th c.). It will survey and analyze inks/pigments in situ with portable instruments, reconstruct and test lab replicas, model degradation under controlled environments, evaluate and optimize stabilization treatments, and operationalize a searchable database (Kateeb) tied to QNL metadata, delivering conservation guidelines, spectral libraries, and capacity-building with Qatar museums and QNL. The plan complements the technology and AI, and the preventive conservation and materials analysis working groups proposed with QLM, QRDI, and QM, and leverages advanced characterization methods, including XRF, Raman/FTIR/XRD, and QNL/QEERI labs. Outputs include curated datasets, validated protocols, and practitioner training that position Qatar as a regional leader in conservation science.